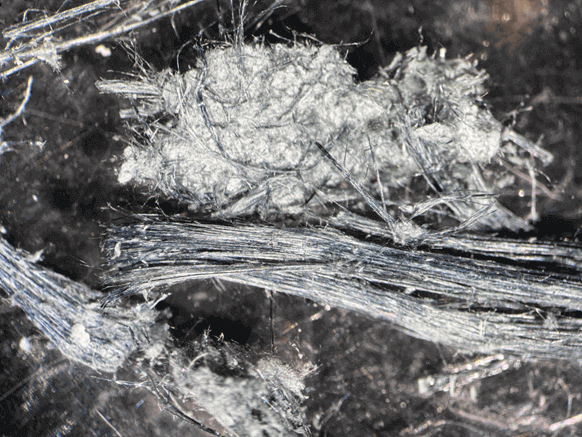

The image above is a non-AI close-up of an asbestos sample containing crocidolite, one of several familiar types of asbestos. If it seems like it resembles barbed wire, that’s exactly how asbestos harms the human body. These fibres can lodge themselves into the tissues and tear them to the point of later manifesting into cancer.

But another thing that makes this image remarkable is that it proves how far we’ve come in our campaign against asbestos. We didn’t know better about the material being a serious health risk decades ago, and even if we did, we lacked the technology to detect it. Even if the tools used date back over a century, the idea of asbestos testing only came much later.

Now that we have the means, it’s only reasonable to make the most out of them and save more lives in the process. Control measures are essential to prevent the spread of asbestos fibres. However, accreditation is crucial to ensure that asbestos testing laboratories meet specific standards. Here are different methods of asbestos testing in Sydney as per AS 4964, an Australian Standard that all National Association of Testing Authorities (NATA)-accredited labs comply with. These techniques are crucial for the analysis and evaluation of asbestos, which is essential for better and risk management and remediation.

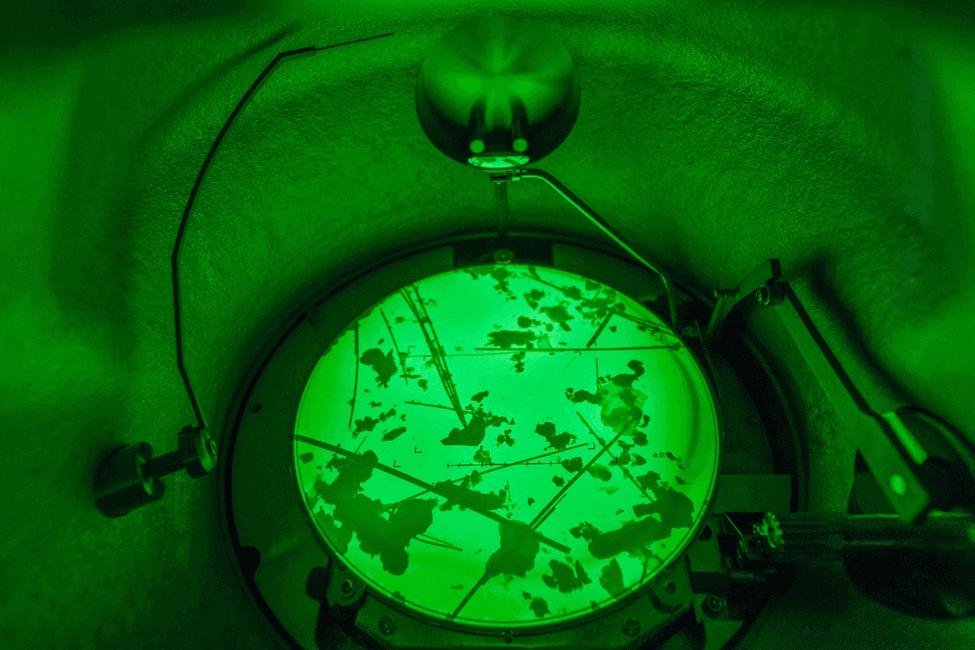

Polarised Light Microscopy (PLM) with Dispersion Staining

Ask any asbestos removal professional about the most common method, and most will say PLM. You won’t find an asbestos testing lab that doesn’t perform PLM with dispersion staining, not only because AS 4964 mandates it, but it’s also practically the gold standard of asbestos testing worldwide.

Sampling of materials is a critical step in asbestos testing. This method attempts to utilise asbestos fibre’s ability to alternate between light and dark shades while being rotated, a property called birefringence. However, shining regular light on the asbestos sample won’t be effective, as it tends to split and move at different speeds when passing through a birefringent material like asbestos.

PLM solves this by making the light pass through a polariser before shining on the sample. Another polariser closer to the viewer recombines the split light waves to create a clearer picture of the sample.

The second half of this method, dispersion staining, helps identify the type of asbestos by analysing its wavelength. Some types are identifiable by their colour, such as chrysotile’s white and crocidolite’s blue. Dispersion staining confirms their colour further.

Because of this, PLM with dispersion staining is widely used for identifying what we call the Big Three of asbestos: amosite, chrysotile and crocidolite. It also produces results quickly, around 15 to 60 minutes, and its widespread use makes it inexpensive. However, one huge downside is that it struggles to identify types of asbestos outside of the Big Three.

Under AS 4964, NATA-accredited labs should report them as “mineral fibres of unknown type.” They’re also advised to identify them with another testing method, which is where the next one comes in.

Scanning Electron Microscopy with Energy Dispersive X-ray (SEM-EDX)

Whereas amosite, chrysotile, and crocidolite asbestos can be discerned by their colour, actinolite, anthophyllite and tremolite asbestos can’t. Not because they don’t come in certain colours, but rather because they share some colours. For example, anthophyllite can also appear brown just like amosite.

This is one reason asbestos testing takes time, as labs want to be certain of the asbestos they’re testing. In this case, instead of light, asbestos testing will involve bombarding the sample with electrons and X-rays. This is known as SEM-EDX.

The science behind SEM-EDX is complicated, and we’ll be here for ages trying to put it in layman’s terms. All you need to know, at least for now, is that the sample’s exposure to electrons and X-rays generates valuable data, from its topography to chemical makeup. This method also works on the Big Three asbestos.

As of this writing, NATA has yet to formalise SEM-EDX as an accredited asbestos testing method. For all its benefits such as the ability to discern types of asbestos that PLM can’t, the cost of the necessary equipment is prohibitive. Additionally, unlike PLM, NATA has yet to develop a standardised methodology for SEM-EDX.

That isn’t to say that accredited labs that solely use this procedure don’t exist. In 2019, NATA accredited a lab in Western Australia that primarily employs SEM-EDX, which the latter claimed as being the first of its kind in the country. Also, as the procedure is also widely used in other areas of materials science, it can be trusted to deliver.

Other Methods

As we’ve established so far, PLM with dispersion staining is the standardised method for asbestos testing and SEM-EDX is often only used when the former doesn’t yield results. That said, other asbestos testing methods exist but are typically more limited than the two in terms of capability and application.

One is transmission electron microscopy (TEM), which uses a high-powered microscope that harnesses electrons instead of natural light, similar to SEM. The difference is that the electrons in this approach pass through the sample, unlike SEM maps the image by finding knocked-off electrons.

TEM produces higher-resolution images than SEM but comes at a high cost. Considering testing costs are passed to clients, SEM has the advantage and, thus, is more preferred. Property owners are more likely to be discouraged with a hefty enough price tag on testing.

Another method is phase contrast microscopy (PEM), which produces quality visuals of colourless samples without the need for dispersion staining. While this reduces testing costs, its images are far less accurate than the other asbestos testing methods discussed so far.